AYLONA T10 Contract Theatre Cultural Seat

AYLONA T10 Contract Theatre Cultural Seat

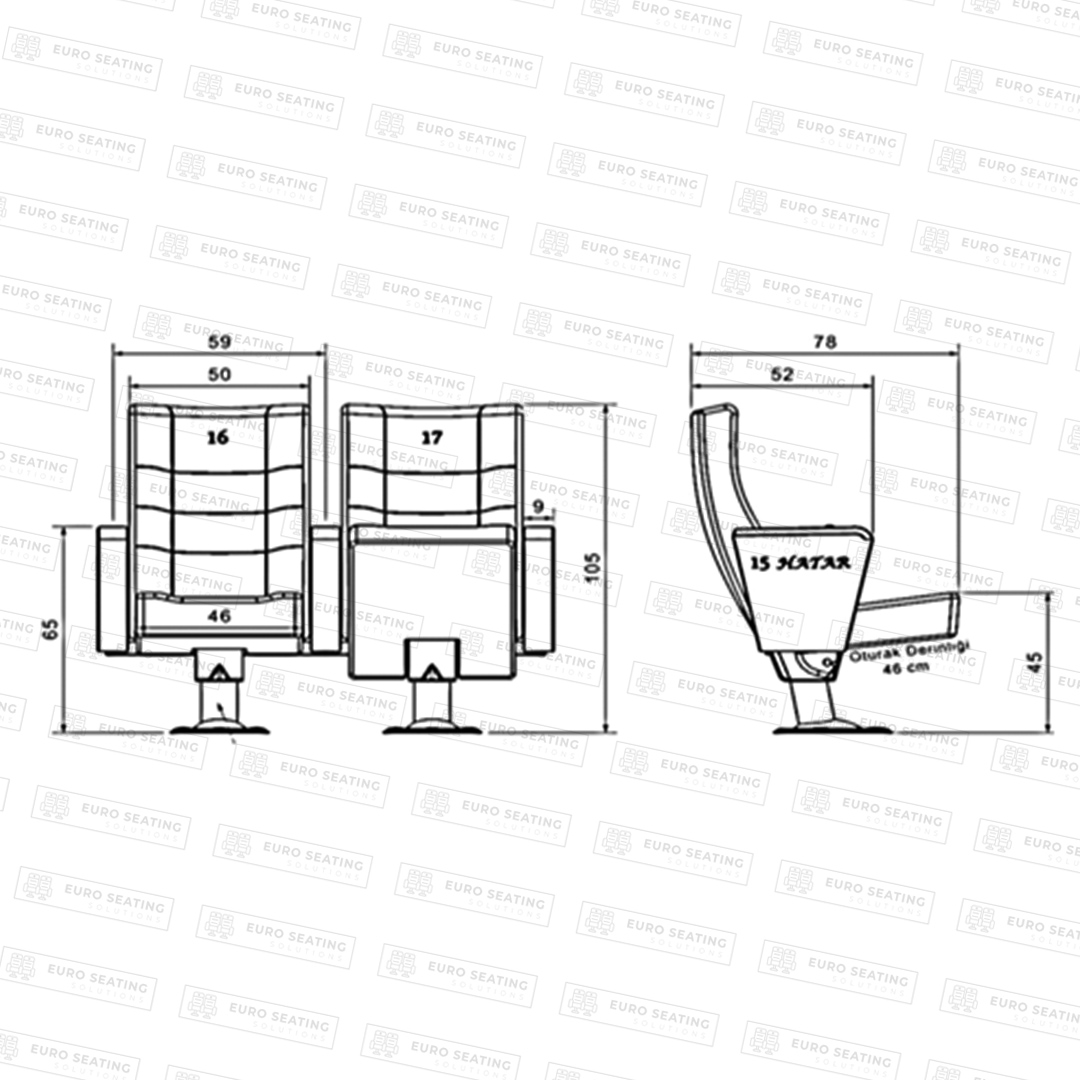

- Conference Chair With Wooden Back

- armchair with one central leg

AYLONA T10 Contract Theatre Cultural Seat

Conference Chair With Wooden Back and Upholstered Seat, Specially Designed for Theaters, Opera Houses, University Halls, and Classrooms in University Colleges, in Addition to Chairs for Parliaments, Ministerial Councils, Conferences, and Local Councils.

TECHNICAL SPECIFICATIONS

-The seat part of the seat will be of the desired softness and will have an internal skeleton made of 20x20x2mm thick profile material. When the seat is not sat on, the seat will be in the closed position. There will be a spring mechanism that allows the seat to open and close.

-The seats will be ergonomic in shape and appearance, the backrest unit, armrests, seat and foot will be mounted firmly to the seat frame, there will be no shaking or gap in the connection system.

-The backrest frames of the seats will be manufactured from profile material with a thickness of at least 15x15x1.5 mm.

-The armrest boxes of the seats will be made of MDF material. It will be covered with 4mm laminated fabric and will be common between the two seats. A polished wooden armrest made of beech material will be mounted on the armrest frame. The armrests will have an ergonomic structure and appearance.

-The seat will be made with a single leg connected to the floor in the middle.

-The seat foot connection will be made of a round pipe with a diameter of 100 mm and a wall thickness of 2.5 mm

-The seats will be single-legged, molded from sheet metal with a thickness of at least 2.5 mm, able to fully touch the ground, and will be able to be fixed to the ground with at least 3 fasteners on each leg.

-In the seat and backrest sponges of the seats, 50 ± 5% density cast polyurethane sponge will be used, the thickness of the thinnest part (both in the seat and the recliner) will not fall below 8 cm. The sponges will have a fireproof feature in accordance with the MVSS 302 European standard.

-The fabrics to be upholstered will be in accordance with the M1 fireproof standards

-The fabrics to be upholstered will be laminated in accordance with the flame method technique with a thickness of 4 mm and a lining will be applied on them

-The seats will be fixed to the ground with suitable fasteners. There will be no shaking or gaps in the seats.

-The seat and back sponges of the seats will be completely covered with fabric and a 12 mm thick polished wooden cover will be mounted on the back of the backrest so that the connection bolts are not visible.

-All welding processes of the construction will be done with gas welding and will be continuous at the joints. The welded seams of the exposed parts of the steel frame joints will be on the inner surfaces.

-The foot connection bolts of the seats tightened to the floor will be covered with plastic plugs.

-The burrs and roughnesses that will occur on the steel frame of the seat due to welding will be ground.

-The metal parts of the seats will be painted with electrostatic black powder paint.