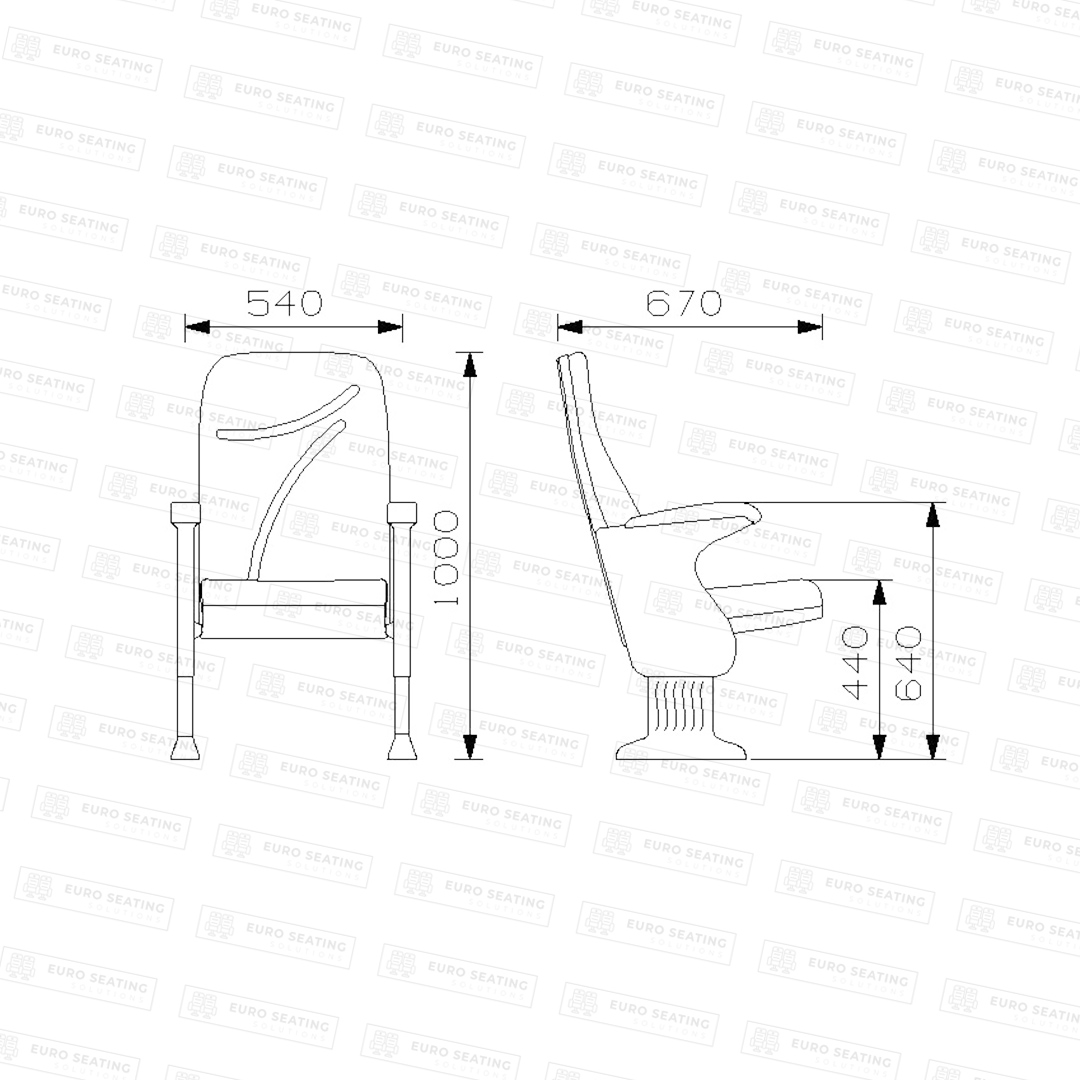

Quality Econ P30 Auditorium Seating with PP Legs

Quality Econ P30 Auditorium Seating with PP Legs

- High Quality PP Lregs Auditorium Chair and armest

- European design 2025

TECHNICAL SPECIFICATIONS

1. The seat part of the seats will have the desired softness and a gravity-centered mechanism that will allow it to close automatically

2. The seats will be ergonomic in shape and appearance, the backrest unit, armrests, seat and foot will be mounted firmly to the seat frame, there will be no shaking or gaps in the connection system.

3. At least Ø16x1.5 mm pipe or at least 15x15x1.5 mm profile material will be used in the metal frames of the seat and backrests.

4. At least three pieces of sheet metal, profile will be welded between the seat frame frames, in the backrests and at least two pieces of sheet metal, profile will be welded in the seats, to increase the strength of the frame.

5. The outer frame of the plastic foot frames of the seats will have a minimum of 8 mm. The plastic feet will be produced as right, left and middle feet. Armrests made of high density (60 ±5 shore A) polyurethane material will be mounted on the plastic foot frame. The armrests will have an ergonomic structure and appearance.

6. Plastic feet will be tightened to the floor from two points and the bolts at the tightened places will be covered with plastic plugs

7. The assembly of the seat backs will be made with a boltless tight fit method to the mechanism made of Polyamide (PA) material mounted on the feet.

8. The armrests of the plastic feet will be covered with fabric-upholstered plastic covers

9. Plastic plugs will be used to prevent the foot connection bolts of the seats tightened to the floor from being visible

10. In the seating and backrest units of the seats, 50 ± 10% density cast polyurethane sponge will be used so that the skeletons remain inside the sponge.

2/2

11. The thickness of the thinnest part of the seat and backrest sponges of the seats (both in the seat and the recliner) shall not fall below 3 cm and shall have a hardness that will not cause permanent deformation. The sponge shall be homogeneous and orthopedic throughout the entire surface. The sponges shall have MVSS

302 European standard non-flammability

12. Fabrics shall be mounted on the seat and back surfaces by gluing

13. A hard plastic polypropylene material with acoustic holes (in the seat and back) shall be used on the back surface of the backrest and the lower surface of the seat

14. There shall be seamless ventilation channels on the backrest surfaces of the seats to prevent sweating

15. The seats shall be fixed with suitable fasteners to the floor. There shall be no shaking or gaps in the seats.

16. All welding processes of the construction shall be made with gas welding and shall be continuous at the joints. The welded seams of the exposed parts in the joints of the steel frame will be on the inner surfaces.

17. The burrs and roughnesses that will occur due to welding on the steel frame of the seat will be ground.

18. The metal parts of the seats will be painted with electrostatic powder paint.