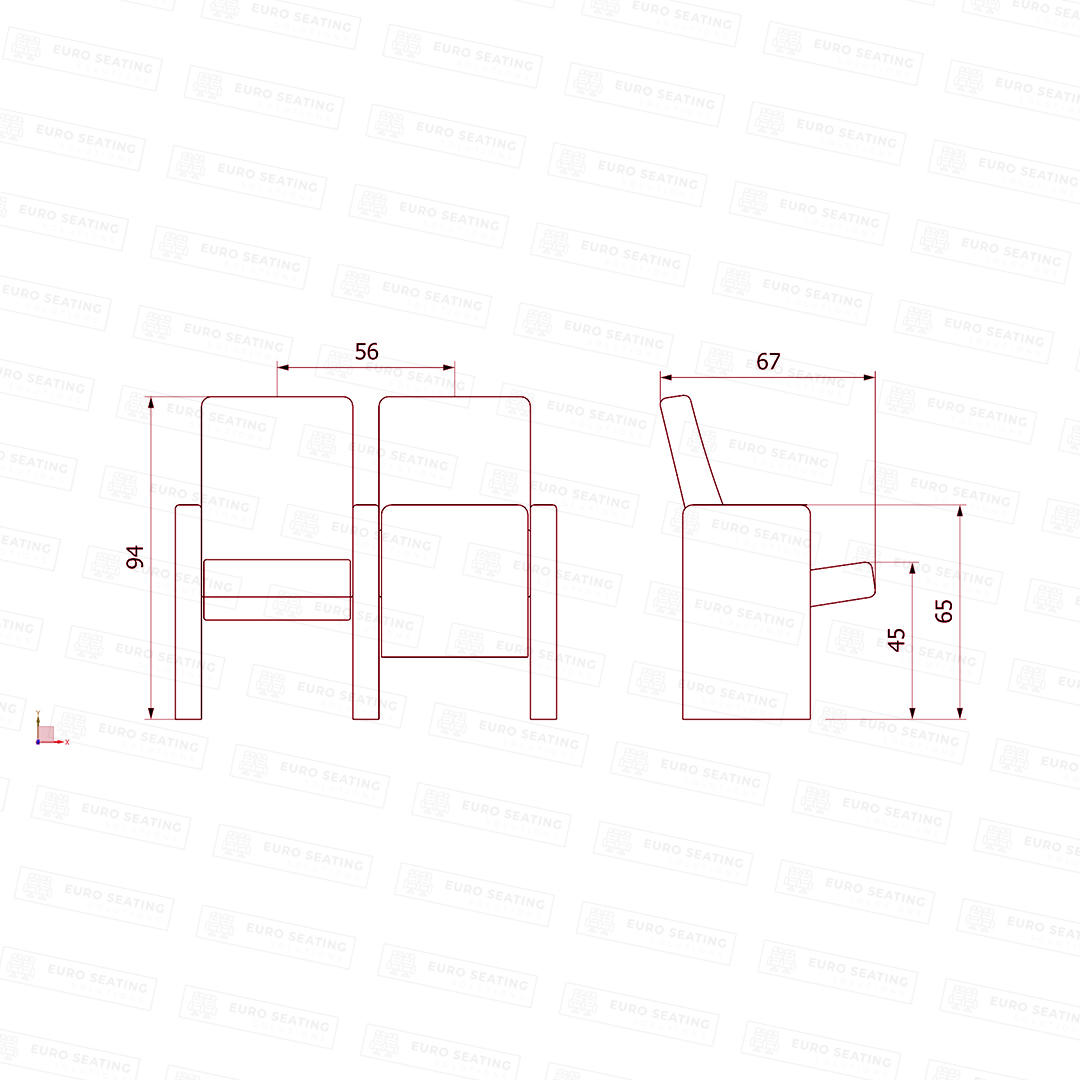

Moona K40 Auditorium Theater Seats

Moona K40 Auditorium Theater Seats

- - Optionally, a fire barrier can be incorporated between the upholstery and the PUR foam.

- Fire standards: complies with international regulations.

This chair is characterized by a design suitable for conference halls, opera houses and theaters. We can also use it in lecture halls in colleges and universities, as it is and flexible in closing, and full upholstery for the chair.

TECHNICAL SPECIFICATIONS

1. The seat part of the seats will have the desired softness and will have a gravity-centered mechanism that will allow it to close automatically

2. The seats will be ergonomic in shape and appearance, the backrest unit, armrests, seat and foot will be mounted firmly to the seat frame, there will be no shaking or gaps in the connection system.

3. At least Ø16x1.5 mm pipe or at least 15x15x1.5 mm profile material will be used in the metal frames of the seat and backrests.

4. At least three pieces of sheet metal and profile will be welded between the seat frame frames, in the backrests and at least two pieces in the seats, to increase the strength of the frame.

5. The feet of the seats will be manufactured from MDF material. The upholstery will be covered with 4 mm laminated suuni leather or fabric

6. The assembly of the seat backs will be made with a boltless tight fit method to the mechanism made of Polyamide (PA) material mounted on the legs

7. The seat legs will be made of 6 mm thick sheet metal material that can fully touch the floor and will be fixed to the floor with a total of 4 fastening elements, at least two on each leg

8. All of the seats made in rows will be closed to the floor.

9. In the seat and backrest units of the seats, 50 ± 10% density cast polyurethane sponge will be used, with the skeletons remaining inside the sponge.

10. The fabrics to be upholstered will be laminated in accordance with the flame method technique with a thickness of 4 mm

11. The thickness of the thinnest part of the seat and backrest sponges of the seats (both in the seat and the reclining area) will not fall below 6 cm and will have a hardness that will not cause permanent deformation. The sponge will be homogeneous and orthopedic throughout the entire surface. The sponges will have MVSS 302 European standard fireproofing

12. The seat and back sponges of the seats will be manufactured completely covered with fabric

13. The seats will be fixed to the ground with suitable fasteners. There will be no shaking or gaps in the seats.

14. All welding processes of the construction will be done with gas welding and will be continuous at the joints. The welded seams of the exposed parts at the joints of the steel frame will be on the inner surfaces.

15. The burrs and roughnesses that will occur due to welding on the steel frame of the seat will be ground.

16. The metal parts of the seats will be painted with electrostatic powder paint.